Latest Entries »

San Joaquín Private Reserve

San Joaquín Private Reserve

70% Dark Chocolate

San Joaquin Reserva Privada is a robust, smooth, silky and sublime chocolate, which highlights delicate tones of fruity acids. Together, these produce a long, balanced cacao linger on the palette. It is a true tribute to the tradition and quality of Venezuelan Cacao, the passion and dedication of the cacao growers and the delicate blend of art and science provided by the El Rey family.

To craft this chocolate of limited and numbered production, we utilize a descendant of the great Ocumare type Cacao, originally from the north central region of Venezuela. Then, with painstaking care during each step of the industrial process, the result is a product that not only pays homage to this exceptional cacao, but becomes a point of reference on the short list of Premium Chocolates known around the world.

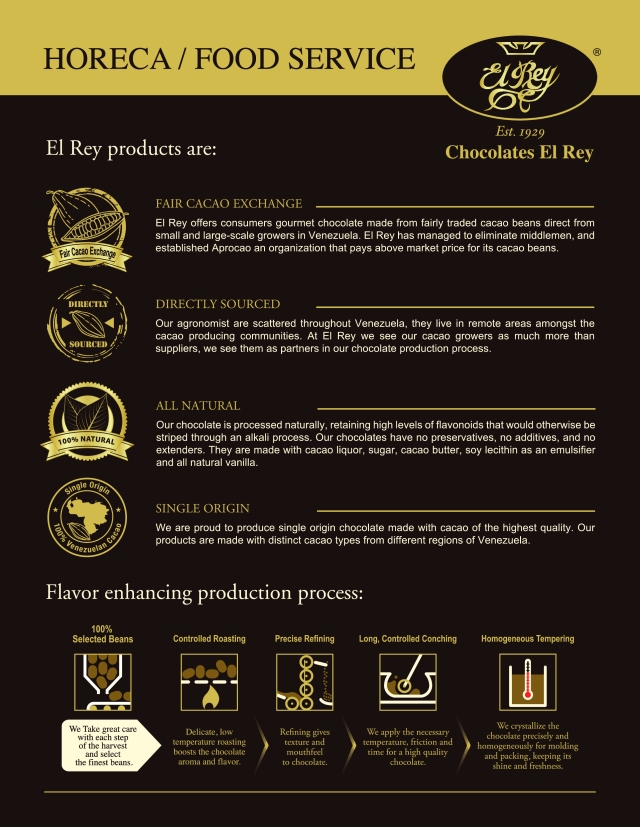

If you visit the El Rey factory in Barquisimeto everyone will tell you that the secret to the company’s success is in the relentless and uncompromising pursuit of quality. The term quality in and of itself might seem a bit broad, but at El Rey we have refined it to a science. Our people on the production line will tell you that to make quality chocolate, one needs to focus on so much more than just the making of the chocolate. In the plant, selecting the beans by size, roasting, refining, tempering, molding and packaging are all critical steps of the process. However, long before the cacao beans arrive at the factory the focus needs to be on fermentation, drying, storage and transport of the beans. Each of these steps set the stage for the making of a premium product.

Most chocolate manufactures import their cacao from producing countries and thus don’t have the monitoring capability of making sure their producers use proper post-harvest processes. True chocolate flavor originates on the farm.

Cacao beans don’t undergo fermentation by themselves. The pulp that surrounds the beans is a key element to the fermentation and it is what in the end projects the flavor and aroma of the bean. Many cacao producers will scoop out the beans from the pod, separating them from the placenta, then immediately place the beans to dry. The proper process consists of placing the pulp covered beans in fermentation bins and progressively stir or mix them over a period of several days. Fermentation initiates when natural sugars are converted into alcohols, the alcohols are then converted into acids and finally the acids are dissipated into the atmosphere. The total fermenting time required depends on the type of bean. The Forester bean usually requires anywhere from 5 to 7 days while the Criollo bean only 1 to 3 days.

Once the beans have been properly fer mented, they are then laid out evenly and set to dry in the sun. Sun drying essentially allows enough time for the curing of the beans. Once the moisture in the beans is measured at less than 1%, they are considered properly dried. They should then be stored in dry areas to prevent the creation of mold.

mented, they are then laid out evenly and set to dry in the sun. Sun drying essentially allows enough time for the curing of the beans. Once the moisture in the beans is measured at less than 1%, they are considered properly dried. They should then be stored in dry areas to prevent the creation of mold.

A bean that has not been fermented properly will not have the usual color characteristics and the fruity acidic flavor associated with cacao. Worst yet is a cacao bean that has not been dried or stored properly. The presence of moisture is a factor that can increase the cacao beans susceptibility to mold, and if this remains unchecked, can wipe out much the flavor and aromatic characteristics achieved during a proper fermentation. For this reason, Chocolates El Rey long ago decided to monitor its raw material from origin all the way through up until the finished product.

We understand that great chocolate originates in the bean. Our agricultural engineers assist small medium and large cacao growers all over Venezuela. They habitually provide workshops that teach new, up and coming farmers how to manage the soil in a sustainable system promoting natural cycles without chemical pesticides or fertilizers. We also monitor and provide support to our growers with proper fermenting and drying methods. At El Rey, we see our cacao growers as partners in our chocolate production process. That is why we pay above international market prices for our beans, in efforts to motivate others to produce higher yields as well as better quality cacao. What sets us apart from other chocolate companies is that we don’t exclusively see ourselves as chocolate manufacturers but rather as a company focused on being a world class agribusiness.

Yield: 3 dozen biscotti

8 oz. milk chocolate, finely chopped

1/3 c. heavy cream

2 Tbls. butter, at room temperature

2 Tbls. bourbon

1 lb. milk chocolate, melted and tempered

• Finely chop the milk chocolate.

• Bring the heavy cream to a boil. Remove from the heat and add chocolate.

• Whisk together until the chocolate melts and the mixture is smooth.

• Add soft butter and bourbon to the chocolate mixture. Whisk together until combined (do not over mix)When you add the butter, the ganache should be about the same temperature as the butter (do not add butter to a hot ganache).

• Allow the ganache to harden and then allow the ganache to sit overnight.

• Scoop truffles with a melon baller. Fill the scoop 3/4 full for average size truffles.

• Round each truffle between your palms. Chill slightly before dipping or rolling them.

Temper the chocolate:

• Slowly melt 10 oz. milk chocolate in a double boiler. Melt over steaming but not simmering water.

• Meanwhile, chop the remaining 6 oz. chocolate.

• The temperature of the chocolate should reach 120 degrees (slightly hot to touch).

• Remove chocolate from heat.

• Add a handful of the chopped chocolate to the ganache.

• Stir until the chocolate is melted.

• Repeat this procedure.

• Continue adding chopped chocolate and stirring until chocolate begins to set up around the edges of the bowl. The chocolate in the center of the bowl should harden within 1 1 / 2 minutes. (Test by dipping a knife into it.)

• The chocolate is now ready to use. If there are any unmelted bits of chocolate in the bowl, move them to the side of the bowl.

• Should the chocolate harden too much to use, place the bowl of chocolate over a pot of hot water just long enough to warm the chocolate (do not return the chocolate to direct heat).

For rolling the truffles:

• Place a little of the tempered milk chocolate on each palm.

• Dip a truffle into the chocolate (halfway or so) and roll the truffle between your palms until coated with chocolate.

• Set the rolled truffle on a sheetpan lined with parchment paper to dry. If the chocolate is properly tempered and you are in a cool room, refrigeration should not be necessary. The chocolate should harden within 1 1/2 minutes. If it doesn’t, the chocolate is too warm and not properly tempered.

• Repeat this process. Each truffle should have 2 coats of chocolate.

Yield: 2 dozen medium-sized truffles

Variations:

• Dip the truffles in tempered milk chocolate. Use a dipping fork and remove as much excess chocolate as possible to avoid a “foot” at the base. The dipped truffles may be decorated with white chocolate by drizzling the white chocolate over the truffles or by using a parchment bag to pipe it in a design.

• Roll the truffles (as explained above) and then drop them into cocoa powder, ground nuts, or nibs, coating on all sides. This will change the appearance, texture, and flavor of the truffles.

• To achieve a spiky appearance, roll the truffles around on a wire rack after the second coating of chocolate.

Recipe:

¼ c. cocoa

6 oz. almonds, toasted

1 ½ c. sugar

8 oz. El Rey Bucare 58.5% or Mijao 61% chocolate

12 Tbls. butter (or 6 oz.)

6 eggs, separated

lc. all purpose flour, sifted

1/8 tsp. salt

• Melt the chocolate.

• Grind the almonds and ½ c. sugar in a food processor. Add the cocoa.

• Cream the butter and ½ c. sugar. Then, add the egg yolks, one at a time, scrapping the sides of the mixing bowl.

• Combine the egg mixture, the chocolate, and the ground almonds. Mix together (mixture will be dry and crumbly).

• Whip egg whites to stiff peak, gradually adding remaining ½ c. sugar.

• Mix 1/3 egg whites into chocolate mixture (to aerate the chocolate mixture). Then, fold in the remaining egg whites.

• Pour into a 10” spring form pan that has been sprayed with baker’s spray and lined at the bottom with parchment paper.

• Bake @ 350 degrees for 15 minutes. Turn down the oven to 325 degrees and continue baking another 30 to 40 minutes or until done. The cake will rise and be firm in the center when ready.

• Allow cake to cool completely.

• Using a cake knife, trim the top of the cake until it is level. Remove the entire top layer as it tends to be fragile and crusty.

• Brush away the crumbs.

Variations:

• This cake can be prepared using pecans or hazelnuts.

• This cake also tastes wonderful served warm with some powdered sugar on top. If you opt to serve the cake this way, do not trim the top.

Ganache

8 oz. El Rey Apamate 73.5% chocolate

l c. heavy cream

2 oz. almonds, toasted and ground

• Melt chocolate in a double boiler.

• Heat heavy cream to the boiling point.

• Add heavy cream to the chocolate and whisk together.

• To finish, place the cake on a 10” cake circle or on the inverted spring form base.

• Place a cooling rack atop a clean sheetpan. Put the cake on the cooling rack.

• Pour the ganache over the cake, covering as much as possible. Use an offset spatula to scrape off the excess ganache and level the top of the cake.

• Allow the ganache to harden somewhat, then press the ground nuts onto the sides of the cake.

• Refrigerate.

Note: if you would like to transfer the cake to a nice serving platter, partially freezing the cake will make it much easier to move.

Raspberry Cream

2c. heavy cream

1/3 c. sugar

20 raspberries

½ tsp. vanilla

• Puree the raspberries

• Whip the heavy cream, sugar, and vanilla until stiff

• Add the raspberry puree. Whisk together until combined.

Note: When whipping heavy cream, be careful not to over-whip it. The cream must be

stiff enough to pipe from a pastry bag. Over- whipping the cream will make it grainy

and cause it to separate.

Chocolate Garnish

8 oz. El Rey Apamate 73.5% chocolate

• Temper the chocolate by melting and heating in a double boiler to 86 degrees.

• Using an offset spatula spread the chocolate on a sheet of parchment paper. Be sure to spread an area larger than the base of the spring form pan.

• When the chocolate has begun to set up (it will no longer have the very shiny appearance it had when melted), lay the base of the spring form pan over it and cut out a circle.

• Cut the circle into 8, 12, or 16 pieces — however many slices you want to cut your cake. By this time, the chocolate will probably have set up. Dip your knife in hot water, and then dry it. The warmth of the knife will allow you to continue cutting the chocolate.

• As long as it is stored in a cool place — not the refrigerator — the chocolate garnish can be prepared well in advance.

• Just before putting the chocolate garnish on the cake, sift powdered sugar over the top.

Vanilla Sauce

2 c. half and half

½ vanilla bean, scraped

6 egg yolks

½ c. sugar

• Whisk together sugar and egg yolks.

• Scrape the vanilla bean into the half and half

• Bring the half and half to a boil.

• Just before the boiling point, pour half of the liquid into the egg mixture and whisk together. (This will temper the eggs.)

• When the half and half boils, add the egg mixture to the boiling liquid and turn down heat to medium.

• Stir the sauce while it is cooking.

• Cook the sauce until it thickens and coats the back of the wooden spoon.

• Strain the sauce, pouring it into a clean container.

• Cool the sauce in an ice-water bath, stirring occasionally as it cools.

Note: If you overcook the sauce, it will separate. If this happens, blend it immediately using a hand-held blender. Usually, this will save the sauce.

The First operation carried out by chocolate makers is cleaning the beans, that is assuring that all extraneous material is separated from the bean: dirt, stones, etc. The beans are then roasted at anywhere between 100 to 150 degrees centigrade for between 20 and 40 minutes depending on the quality of the beans and the desired aroma of the final product. Once roasted the shell becomes very brittle and is separated from the bean (nib) by way of vibration. The separation of the shell from the bean or nib is called winnowing or shelling.

Nibs of different origins are then blended in accordance to the recipe for the desired chocolate to be processed. These are then ground in high speed mills at high temperature (50 to 70 degrees centigrade / 120 to 160 degrees Fahrenheit). The nibs are thus transformed into a viscous paste or mass called Cacao Liquor and the manufacture of chocolate begins.

Part of the production of Liquor is pressed in order to extract cacao butter, an essential ingredient in the making of chocolate, and reserved.

The process begins by mixing the ingredients for the desired chocolate, that is cacao liquor, sugar, vanilla, part of the cacao butter (and milk of the final product is milk chocolate). This mass is then passed through roller mills and refined to reduce the particle size to less than 22 microns.

The next phase is called conching. This stage was invented by a Swiss named Rudolph Lindt, which eliminates the last traces of moisture and acids natural to cacao, and brings out the taste, texture and aroma of the chocolate as well as the final smoothness. The mass is placed into conches where it is slowly kneaded and smoothed. It is at this stage where the remainder of cacao butter is added to the mass, which gives the final product the proper texture and shine.

Once the chocolate has reached the desired texture it is pumped into holding tanks in preparation for the final stages of production. The final stage begins by tempering the chocolate. This is done by briskly reducing the temperature of the chocolate that has been in holding tanks from around 40 degrees centigrade to about 28 degrees. The temperature is then gently raised to around 32 degrees depending on the contents of the mass. This procedure initiates the crystallization or hardening of the chocolate. Proper tempering is very important because this will ensure the final color, shine and stability of the final product.

It is at this stage, when the chocolate begins crystallizing that it is poured into moulds. The mould are vibrated to extract any air bubbles that may have formed and then enter a refrigerated tunnel where the chocolate is solidified. The very last stage involves unmolding and wrapping the chocolate.